Decision Orquestration.

For Critical Engineering.

AI Optimized Workflows.

For All Industries.

Mission

Empowering

high-performance engineering.

Empowering

high-performance engineering.

Outrigo® introduces Morph®: Converting fragmented workflows into a single, interoperable engine for hardware innovation.

Discover Morph®

(Architecture · Validation · Production)

Discover Morph®

(Architecture · Validation · Production)

(04)

From Concept to Production.

From Concept to Production.

Morph®

Morph®

Morph® connects architecture, simulation, validation and manufacturing into a continuous digital-to-physical workflow. This reduces iteration cycles, improves traceability and accelerates certification.

Arquitecture.

Arquitecture.

Define system performance and constraints from the start. Our integrated approach optimises structure, weight and manufacturability in a single environment.

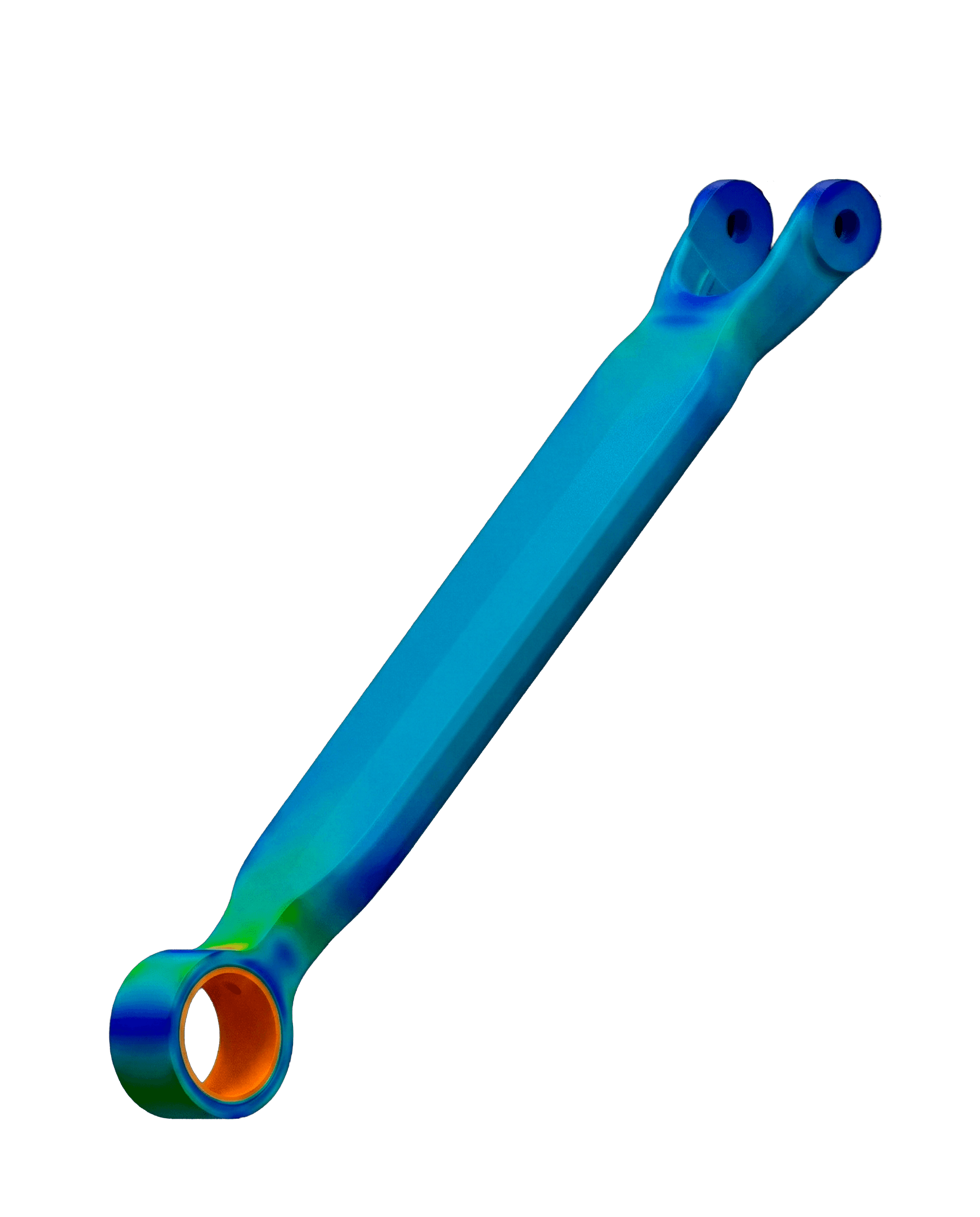

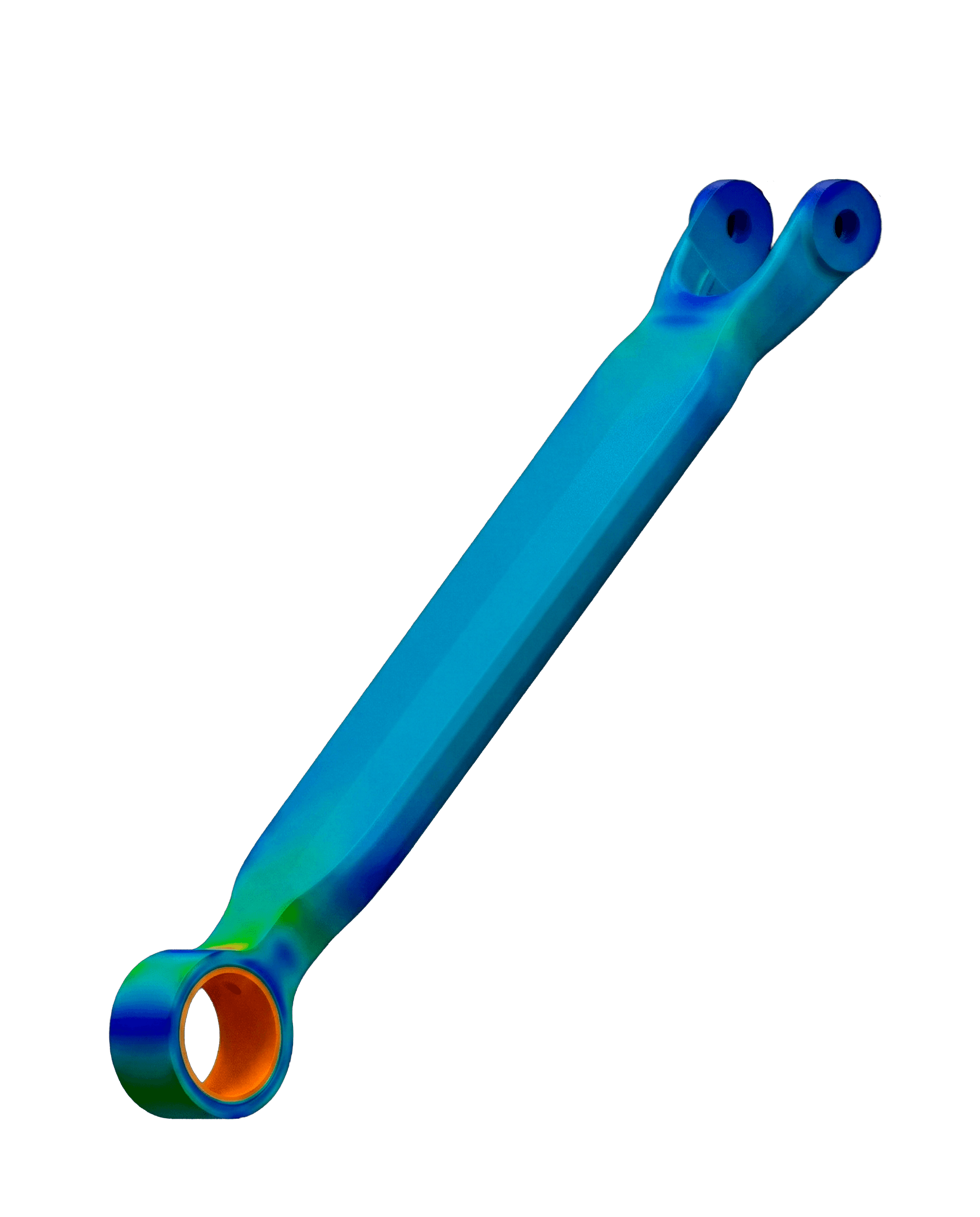

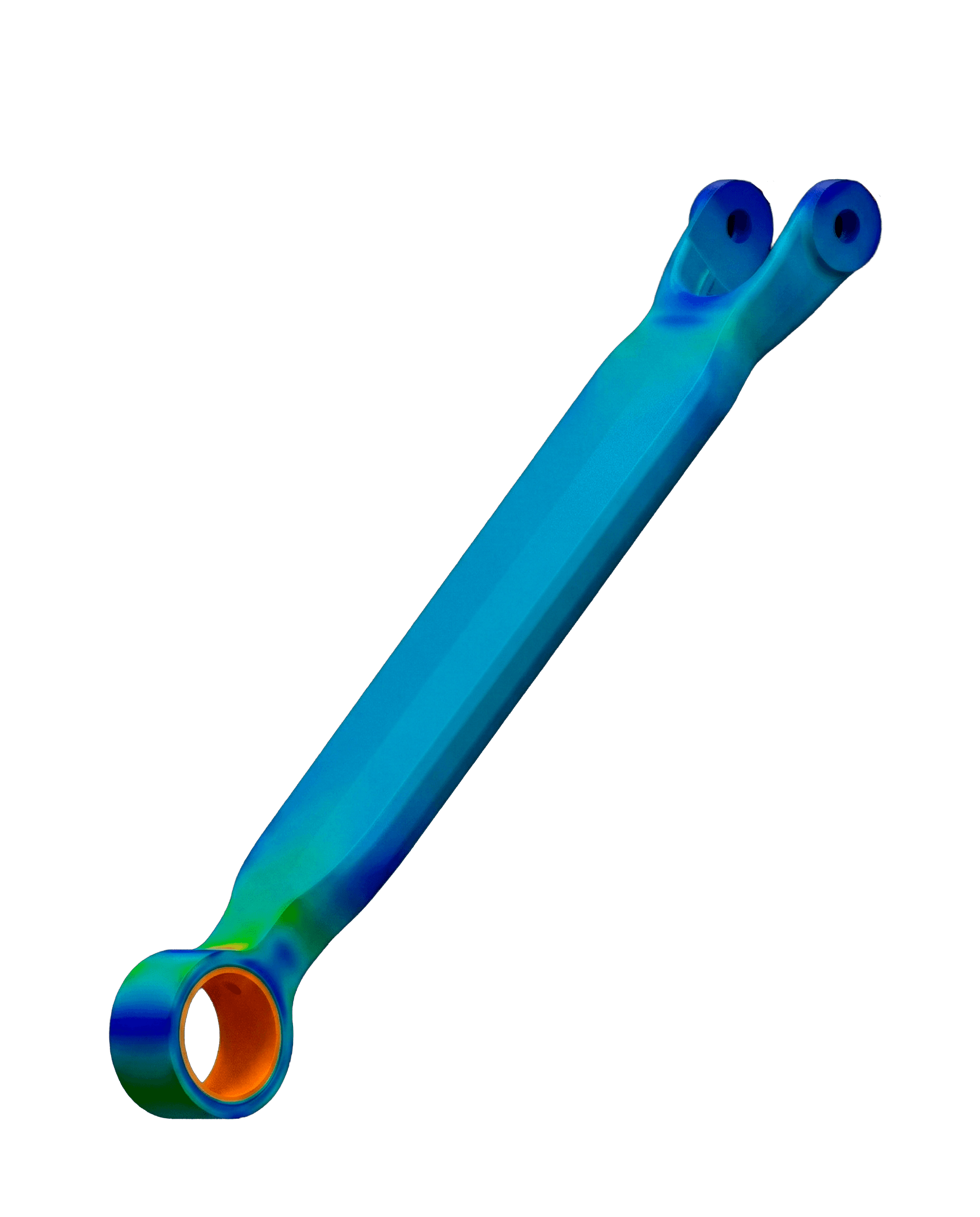

Virtual Validation.

Virtual Validation.

High-fidelity simulation reduces physical testing and improves confidence in performance and safety-critical systems.

Physical Validation.

Physical Validation.

Targeted testing and certification workflows ensure traceability and regulatory alignment.

Adaptive Production.

Adaptive Production.

Additive and advanced manufacturing enable rapid transition from prototype to scalable production.

Arquitecture.

Define system performance and constraints from the start. Our integrated approach optimises structure, weight and manufacturability in a single environment.

Virtual Validation.

High-fidelity simulation reduces physical testing and improves confidence in performance and safety-critical systems.

Physical Validation.

Targeted testing and certification workflows ensure traceability and regulatory alignment.

Adaptive Production.

Additive and advanced manufacturing enable rapid transition from prototype to scalable production.

(06)

Industries.

Industries.

Industries.

We work with organisations developing complex physical systems where performance, safety and time to market are critical. Our integrated approach combines engineering, validation and adaptive manufacturing to support the full lifecycle.

We work with organisations developing complex physical systems where performance, safety and time to market are critical. Our integrated approach combines engineering, validation and adaptive manufacturing to support the full lifecycle.

We work with organisations developing complex physical systems where performance, safety and time to market are critical. Our integrated approach combines engineering, validation and adaptive manufacturing to support the full lifecycle.

(04)

One platform, complete lifecycle.

Engineering clarity for high-consequence systems.

Certified Compliance

Built for secure, traceable and regulated environments across aerospace, defence and advanced manufacturing.

Risk Mitigation

Protecting intellectual sovereignty and reducing program uncertainty through integrated simulation, validation and production workflows.

Operational Partner

We embed with your teams as a long-term partner, accelerating program milestones and supporting the transition from concept to production.

Proven Methodologies

Our methodologies are already deployed in multi-year, multi-system development programs.

(06)

One platform, complete lifecycle.

Engineering Clarity Where Complexity is Highest.

Certified Compliance

ISO 9001 and 27001 certified infrastructure. Engineered for maximum security and regulatory rigor.

Risk Mitigation

Protecting intellectual sovereignty. Eliminating uncertainty in mission-critical program execution.

Customer Focus

We are not a supplier of isolated services. We are a partner in program success.

Proven Methodologies

Our methodologies are already deployed in complex-system development programs.

Certified Compliance

ISO 9001 and 27001 certified infrastructure. Engineered for maximum security and regulatory rigor.

Risk Mitigation

Protecting intellectual sovereignty. Eliminating uncertainty in mission-critical program execution.

Customer Focus

We are not a supplier of isolated services. We are a partner in program success.

Proven Methodologies

Our methodologies are already deployed in complex-system development programs.

One platform, complete lifecycle.

We’ve helped businesses across industries achieve their goals. Here are some of our recent projects.

(04)

Impact Studies.

Impact Studies.

©2025

We support complex development programs across different industries from early architecture to production readiness.

We support complex development programs across different industries from early architecture to production readiness.

(04)

Impact Studies.

©2025

We support complex development programs across different industries from early architecture to production readiness.

2026 Outrigo®

Talk to our team.

We partner with leading organisations to solve high-consequence engineering challenged. Share your objectives and our team will get in touch.

2026 Outrigo®

Talk to our team.

We partner with leading organisations to solve high-consequence engineering challenged. Share your objectives and our team will get in touch.

Talk to our team.

We partner with leading organisations to solve high-consequence engineering challenged. Share your objectives and our team will get in touch.